Screw feeders

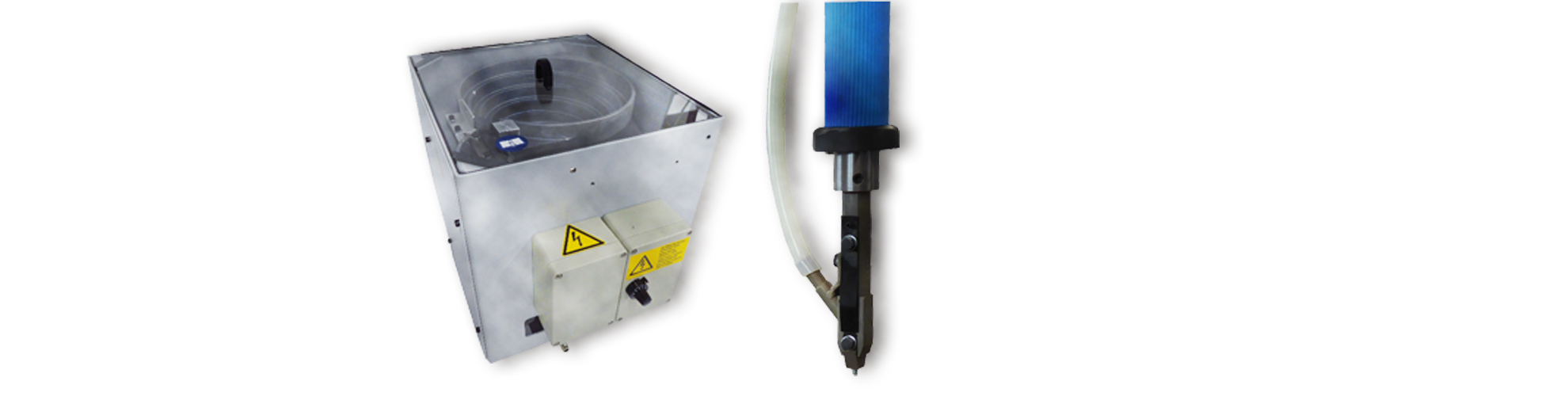

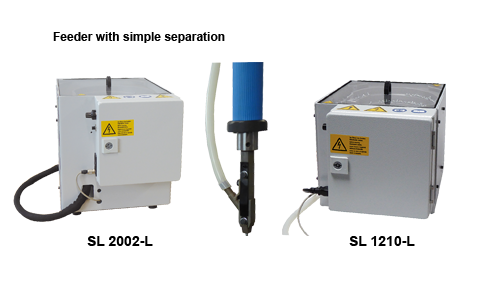

Screwfeeder Series SL 1210-L | SL 2002-L | SL 2002-L-2

Automatic screw feeders ensure efficient production. They can be used with both manual and automated systems. The subsequent conversion to other sizes of screws creates investment security.

Time-consuming work is eliminated. The feeder shoots the screws directly in front of the screwdriver blade. As a result, high cycle times can be achieved and work can be performed efficiently and precisely.

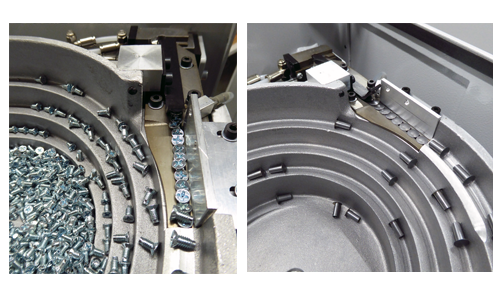

The screws are conveyed from a chute on a rail via a vibratory spiral conveyor and then separated from one another in the separation. Individually, the screws are then shot via the supply hose by compressed air to the screwing tool, where they are processed. The signal for adding another screw is given via the handpiece on the screwdriver or externally. There are two models with one seperation, as well as one which has seperational sections to feed two independently working screwdrivers.

Options

Mechanical guide for feeding the screws, at two different screw points.

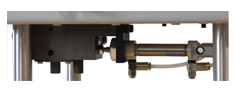

Depth stop

Shut-off of the screwdriver at a certain depth. Especially for applications in wood, where a leveling of the screw head on the surface must be achieved.

Adaptation to screwdrivers

Standard adaptation to screwdrivers with external thread on the front housing. Special adaptations for all common screwdriving tools is possible.

Stroke extension

The standard stroke of the handpiece is designed, that screws can be screwed against a flat surface. For deeper screw points, the stroke can be extended individually.

Feeder in special design

Version with higher feet, e.g. for mounting a guide

Versions with terminal box for external control

Mouthpieces for different applications

Standard mouthpiece: Two jaws hold the head of the screw. Optionally, a lock is possible, which prevents the immersion of the screw in the mouthpiece. This allows a better setting of the screw on the workpiece. Standard mouthpiece is used where the screw can be placed on a flat surface and where there is enough space for the jaws to open laterally

Mouthpiece with ball sleeve:

The screw head is held by balls. In confined spaces, poor accessibility or the use of a screw template, this mouthpiece is ideal.

Further special mouthpieces are available on request.

Technical Data (Subject to change)

| Model | Head-Ø | Screw-Ø | Screw length | Dimensions | Pot vol. | Performance | Weight | Hose cable kit |

| mm | mm | mm | LxWxH | l | Screw/min. | kg | m | |

| SL 1210-L | 2.3-8.0 | 1.3-4.2 | 4 - 25 | 352(439*)x255x252 | 0.6 | 100 | 21 | 3 |

| SL 2002-L | 5.0-10 | 2.5-6.0 | 7 - 55 | 408(495*)x290x325 | 1.5 | 100 | 31 | 4 |

| SL 2002-L-2 | 5.0-10 | 2.5-6.0 | 7 - 55 | 473(560*)x300x325 | 1.5 | 100 | 32 | 4 |

| *incl. Maintenance unit |

All complete screw feeders are equipped with handpiece, mouthpiece, blade holder, blade and spare blade. Longer version hose kits are available (optionally). All models can be used with stroke extensions or sleeve guides.

Technical data (Subject to change)

| Model | Volume | Capacity | Weight | Hose cable set |

| [l] | Srews/min. | [kg] | [m] | |

| SL 1210-L | 0,6 | 100 | 21 | 3 |

| SL 2002-L | 1,5 | 100 | 31 | 4 |

| SL 2002-L-2 | 1,5 | 100 | 32 | 4 |

All information subject to change without further notice.

No responsibility is taken for the correctness of the named specifications.

Product Data sheet

Contact Person

Sale

Mediation via secretary:

Marita Förster

Phone +49-231/91 72 11 - 11

E-Mail: marita.foerster@bahco.de

Service / Order Processing:

Ursula Fietze

Phone +49-231/91 72 11 - 18

E-Mail: ursula.fietze@bahco.de