Electric pneumatic BEG48

Electro Pneumatic Tapping Unit BEG48

The BEG 48-series is a flexible electro-pneumatic unit in a modular design. The electric motor runs the spindle, while the feed is pneumatic. Hydraulic feed control makes it possible to use rapid advance and to adjust the feed rate in proportion to the pitch and the rpm. A tapping collect or a tapping spindle gives the unit the necessary length compensation. The series is available with JT2 taper or integrated ER32 chuck as well as with multi-spindle heads.

• Compact yet flexible design

• Modular hydraulic feed control for the whole stroke

• Smart depth control

• Linear transducer for total control of the complete cycle (optional)

Guidlines for choice of unit [M-Thread]

| Tapping unit | Capacity in Steel | Capacity in Alu. & Brass | Capacity in Wood & Plastics |

| Numbers of spindles | 1 / 2 / 3 / 4 | 1 / 2 / 3 / 4 | 1 / 2 / 3 / 4 |

| BEG481 | M6 / M5 / M4 / M3 | M10 / M8 / M8 / M6 | M14 / M8 / M8 / M8 |

| BEG484 | M8 / M6 / M5 / M5 | M14 / M10 / M8 / M8 | M16 / M14 / M12 / M10 |

| BEG487 | M12 / M8 / M6 / M6 | M20 / M14 / M12 / M10 | M30 / M20 / M20 / M16 |

Performance specifications at 6.3 bar

| Thrust (max.) | 1,650 - 2,000 N | Depth accuracy ± | 0.01 mm |

| Stroke (max. 100% controlled | 100 mm | Rapid advance rate (max.) | 10 m/min. |

| Min. Center to Center spacing | controlled feed rate | > 0.04 m/min. | |

| Single spindle | 90 mm | Air consumption | 2.8 l/100 mm |

| Double-spindle head | 12 mm | Noise level | < 85 dB(A) |

Tapping unit / Motor at V380-420 (Y) / 220-240 (∆) 50 Hz [kW]

| Number of poles | BEG481 | BEG484 | BEG487 |

| 2 | 0.55 | 1.1 | 2.2 |

| 4 | 0.37 | 0.75 | 1.5 |

| 6 | 0.25 | 0.55 | 1.1 |

| 8 | 0.55 |

We do not recommend floating tapping at turns over 2000 U / min. use. In addition, we point out that the max. speed

when cutting reduced in deep holes, blind holes or the use of larger threaded heads.

• Motor specifications shown in the tables are valid for 380-420V (Y)/220-240V (Δ) (±5%), 50Hz. These motors can also

be used at 440-480V (Y) (±5%), 60 Hz. If so the rpm will increase by ~20% and the power by 15% relative to the data

for 50Hz. We also offer motors for other voltages and frequencies. Please state voltage and frequency when requesting

a quote or ordering.

• the torque at the spindle for a specific rpm is calculated as:

M = (P[kW] x 9500) / rpm

Spindle rpm with gear ratio at 50Hz

| Number of poles | 2.5:1 | 2.1:1 | 1.8:1 | 1.6:1 | 1.4:1 | 1.2:1 | 1:1 | 1:1.2 | 1:1.4 | 1:1.6 | 1:1.8 | 1:2.1 | 1:2.5 |

| 2 | 1,130* | 1,350 | 1,580 | 1,770 | |||||||||

| 4 | 560* | 670 | 780 | 860 | 1,030 | 1,190 | 1,390 | 1,620 | 1,880 | ||||

| 6 | 360* | 440 | 510 | 560 | 670 | 780 | 910 | 1,060 | 1,230 | 1,470 | 1,630 | 1,900 | |

| 8 | 270* | 330 | 380 | 420 | 500 | 580 | 680 | 790 | 920 | 1,100 | 1,210 | 1,420 | 1,730* |

* Not available for BEG487!

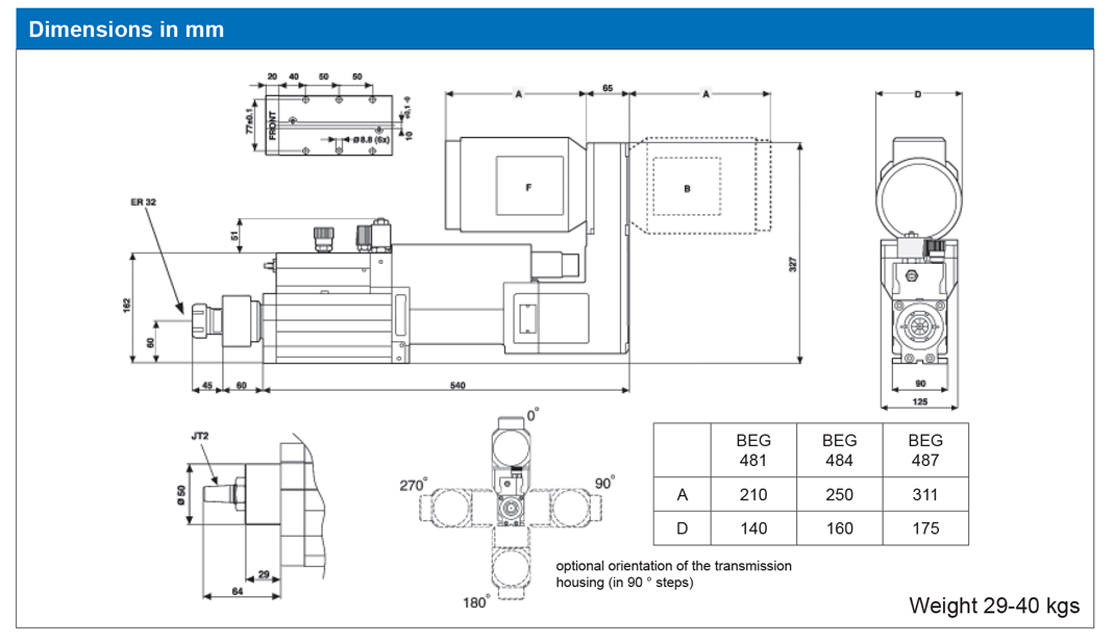

Technical drawing BEG 48

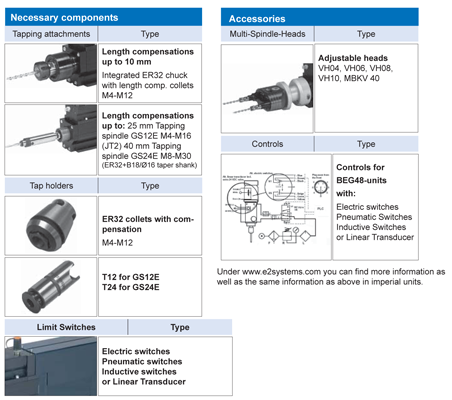

Necessary components and accessories

All information subject to change without further notice.

No responsibility is taken for the correctness of the named specifications.

Technical data sheet

Contact Person

Sale

Mediation via secretary:

Marita Förster

Phone +49-231/91 72 11 - 11

E-Mail: marita.foerster@bahco.de

Service / Order Processing:

Ursula Fietze

Phone +49-231/91 72 11 - 18

E-Mail: ursula.fietze@bahco.de