Workshop presses

Workshop Presses - 10 tons up to 300 tons

The hydraulic workshop presses are suitable for continuous use in the fields of mechanical engineering, metalworking and many other areas in the trades and industry. You will be used for straightening, bending, press-fitting, cutting, cutting and punching. Optionally with air-hydraulic pump or with electric motor pump -one and two-stage in three flow speeds. The electric motor pumps are infinitely variable and equipped with pressure gauges.

Features:

• 33 standard models

• Piston stroke from 190 up to 520 mm

• Welded frame

• Cylinder made of extra hard steel

• Piston hard chromed

• CE tested quality

The application area influences the design of the press!

| Application area | Speed | Safety device |

| Straightening, stock pressing (freehand work) | Slow Version(iP) (Fig. 1) | Accessible from all sides, as a protective grid is not required |

| Straightening, bearing press (sporadic use) | Slow (Fig. 2) | Accessible from all sides, as a protective grid is not required |

| Straightening, testing (daily use) | Version (W) up to 10 mm/sec. (Abb. 2) | Accessible from all sides, as a protective grid is not required |

| In the production process (permanent use) | Version (R) up to 25 mm/sec. (Fig. 3) | + At least three Positions with protective grids fitted + 2-hand simulation control |

The law states that presses with a forward speed greater than 10 mm / sec. must be provided

with at least screens on three sides, and a 2-hand control.

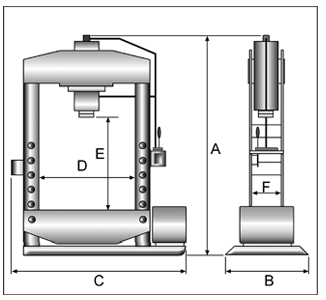

Figures of the different presses

Hydraulic workshop press with air-hydraulic foot pump

| Type | Order-No. | Capacity | Piston stroke | A | B | C | D | E | F | Weight |

| ( tn ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( kgs ) | ||

| 154/iP | 38980021 | 10 | 190 | 1,900 | 500 | 780 | 520 | 980 | 120 | 124 |

| 155/iP | 38980031 | 15 | 190 | 1,890 | 500 | 790 | 510 | 1,020 | 140 | 130 |

| 156/iP | 38980033 | 20 | 200 | 1,920 | 500 | 810 | 510 | 1,020 | 140 | 150 |

| P30/SAiP | 38980035 | 30 | 190 | 2,000 | 600 | 1,270 | 695 | 1,000 | 170 | 280 |

| 157/iP | 38980037 | 40 | 190 | 2,100 | 850 | 1,330 | 770 | 1,135 | 200 | 405 |

| 158/iP | 38980038 | 50 | 190 | 2,110 | 850 | 1,330 | 770 | 1,135 | 210 | 445 |

Standard-equipment:

Air-hydraulic pump for hands-free use with both hands, height-adjustable table, support plate and double prism blocks only

for 154iP / 155iP and 156iP, pressure gauge and winch for table adjustment only with P30/SAiP,157/iP and 158/iP.

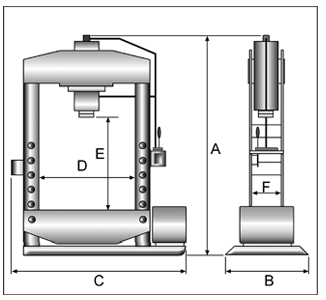

Electro-hydraulic workshop press (slow forward speed) with electric motor pump - single-stage

| Type | Order-No. | Capacity | Piston stroke | A | B | C | D | E | F | Weight |

| ( tn ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( kgs ) | ||

| 154/ML | 38980050 | 10 | 260 | 1,900 | 500 | 1,100 | 520 | 980 | 120 | 174 |

| 156/ML | 38980060 | 20 | 285 | 1,920 | 500 | 1,100 | 510 | 1,000 | 140 | 190 |

| P30/ML | 38980061 | 30 | 260 | 2,000 | 600 | 1,600 | 695 | 1,000 | 170 | 320 |

| 161 | 38980070 | 40 | 260 | 2,070 | 850 | 1,575 | 770 | 1,135 | 200 | 440 |

| 162 | 38980080 | 50 | 260 | 2,080 | 850 | 1,575 | 770 | 1,135 | 210 | 480 |

| 163 | 38980090 | 70 | 310 | 2,205 | 900 | 1,755 | 880 | 1,120 | 270 | 740 |

| 164 | 38980110 | 100 | 310 | 2,260 | 900 | 1,930 | 1,010 | 1,055 | 285 | 1,000 |

Standard-equipment:

Electric motor pump - single-stage, height-adjustable table, standard pressure gauge, lever three-way distributor for freehand work,

winch for table adjustment only with P30 / ML, 161, 162, 163 and 164.

Technical drawing

Electrohydraulic workshop press (flow rate up to 10mm / sec.) With electric pump - two stage

| Type | Order-No. | Capacity | Piston stroke | A | B | C | D | E | F | Weight |

| ( tn ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( kgs ) | ||

| 156/W | 38980121 | 20 | 285 | 1,920 | 500 | 1,110 | 510 | 1,000 | 140 | 200 |

| P30/W | 38980126 | 30 | 260 | 2,000 | 600 | 1,600 | 695 | 1,000 | 170 | 330 |

| 161/W | 38980131 | 40 | 260 | 2,070 | 850 | 1,650 | 775 | 1,135 | 195 | 470 |

| 162/W | 38980141 | 50 | 260 | 2,080 | 850 | 1,650 | 775 | 1,135 | 205 | 530 |

| 163/W | 38980151 | 70 | 310 | 2,205 | 900 | 1,755 | 880 | 1,120 | 265 | 800 |

| 164/W | 38980161 | 100 | 310 | 2,260 | 900 | 1,930 | 1,010 | 1,055 | 280 | 1,050 |

| 164/WS | 38980162 | 100 | 310 | 2,400 | 1,300 | 2,320 | 1,520 | 1,065 | 360 | 1,500 |

| 204/W | 38980172 | 150 | 400 | 2,520 | 1,300 | 2,470 | 1,520 | 1,018 | 410 | 2,200 |

| 204/WE | 38980173 | 150 | 400 | 2,515 | 1,300 | 1,970 | 1,020 | 1,035 | 410 | 1,870 |

| 205/W | 38980221 | 200 | 520 | 2,995 | 1,310 | 2,600 | 1,520 | 1,020 | 520 | 4,150 |

| 280/W | 38980231 | 300 | 500 | 3,415 | 1,700 | 2,900 | 1,500 | 960 | 640 | 8,200 |

Standard-equipment

Electric motor pump -zweistufig- (not for 156 / W P30 / W and 161 / W) handicrafts, lever-three-way manifold for free,

table adjustment winch (at P30 / W 161 / W 162 / W 163 / W and 164 / W), with rod (for 164 / WS, 204 / W and 204 / WE)

or with two hydraulic cylinders (for 205 / W and 280 / W), standard pressure gauge.

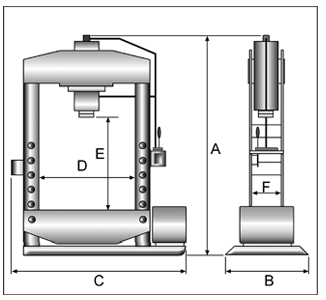

Electrohydraulic workshop press (flow rate up to 25mm / sec.) With electric pump - two stage

| Type | Order-No. | Capacity | Piston stroke | A | B | C | D | E | F | Weight |

| ( tn ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( kgs ) | ||

| 154/MR | 38980115 | 10 | 260 | 1,900 | 500 | 1,100 | 520 | 980 | 120 | 194 |

| 156/MR | 38980120 | 20 | 285 | 1,920 | 500 | 1,110 | 510 | 1,000 | 140 | 208 |

| P30/MR | 38980125 | 30 | 260 | 2,000 | 600 | 1,600 | 695 | 1,000 | 170 | 338 |

| 161/R | 38980130 | 40 | 260 | 2,070 | 850 | 1,650 | 775 | 1,135 | 195 | 530 |

| 162/R | 38980140 | 50 | 260 | 2,080 | 850 | 1,650 | 775 | 1,135 | 205 | 560 |

| 163/R | 38980150 | 70 | 310 | 2,205 | 900 | 1,755 | 880 | 1,120 | 265 | 850 |

| 164/R | 38980160 | 100 | 310 | 2,260 | 900 | 1,930 | 1,010 | 1,055 | 280 | 1,100 |

| 164/RS | 38980190 | 100 | 310 | 2,400 | 1,300 | 2,320 | 1,520 | 1,065 | 360 | 1,500 |

| 204/R | 38980171 | 150 | 400 | 2,520 | 1,300 | 2,470 | 1,520 | 1,018 | 410 | 2,200 |

| 204/RE | 38980170 | 150 | 400 | 2,515 | 1,300 | 1,970 | 1,020 | 1,035 | 410 | 1,870 |

| 205/R | 38980225 | 200 | 520 | 2,995 | 1,310 | 2,600 | 1,520 | 1,020 | 520 | 4,150 |

| 280/R | 38980235 | 300 | 500 | 3,415 | 1,700 | 2,900 | 1,500 | 960 | 640 | 8,200 |

Standard-equipment

Electric motor pump, back and side guard, suction manifold and pressure head on the panel, which must be switched

simultaneously for operation table adjustment winch (at 164 / RS, 204 / R 204 / RE), fitted as standard gauge.

Technical drawing

Tool presses with special dimensions on request!

Electrohydraulic workshop press for metal sheet bending work

| Type | Order-No. | Capacity | Piston stroke | A | B | C | D | E | F | Weight |

| ( tn ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( kgs ) | ||

| 164/RP | 38980250 | 100 | 310 | 2,260 | 900 | 1,950 | 1,050 | 400 | 280 | 1,700 |

| 164/RPA | 38980251 | 100 | 300 | 2,300 | 900 | 1,950 | 1,050 | 400 | 280 | 1,900 |

| 204/RP | 38980252 | 150 | 400 | 2,850 | 1,200 | 2,450 | 1,500 | 400 | 410 | 3,100 |

| 204/RPA | 38980253 | 150 | 400 | 2,850 | 1,200 | 2,550 | 1,500 | 400 | 410 | 3,100 |

Standard-equipment

Electric motor pump - two stage, electric hand switch, 1 special die for 5 bending molds - Creation, three-way lever manifold

and pressure head (164 / RPA and 204 / RPA), rear and laterally protective grille.

Electrohydraulic workshop press with movable stand

| Type | Order-No. | Capacity | Piston stroke | A | B | C | D | E | F | Weight |

| ( tn ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( mm ) | ( kgs ) | ||

| 162/WM | 38980242 | 50 | 500 | 2,400 | 1,600 | 1,500 | 810 | 800 | 205 | N/A |

| 164/WM | 38980243 | 100 | 500 | 2,700 | 1,820 | 1,750 | 1,010 | 1,000 | 285 | N/A |

| 204/WM | 38980244 | 150 | 500 | 2,900 | 2,000 | 1,950 | 1,210 | 1,000 | 360 | N/A |

Standard-equipment

Electric motor pump - two-stage, swiveling cylinder and stand, 1 set of extensions to increase the piston stroke, 1 set of prism blocks,

lever three-way manifold for hands-free operation, standard gauge.

Technical drawing

Workshop presses with special dimensions on request!

| Special accessories: • V blocks / prism blocks • Table tops with three holes • T - groove plates • Centering device • Tool holders (also with rotation stop) • Stroke limits • Press mandrel sets (for workshop presses up to 40tn) • Adjustable cylinder |

All information subject to change without further notice.

No responsibility is taken for the correctness of the named specifications.

Product data sheet

Contact Person

Sale

Mediation via secretary:

Marita Förster

Phone +49-231/91 72 11 - 11

E-Mail: marita.foerster@bahco.de

Service / Order Processing:

Ursula Fietze

Phone +49-231/91 72 11 - 18

E-Mail: ursula.fietze@bahco.de